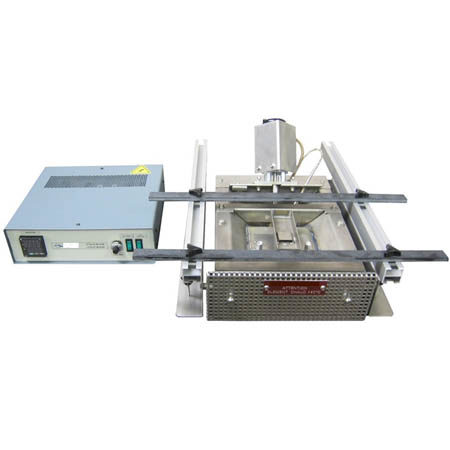

Mains supply 230 V / 50-60 Hz

Power 1350 W

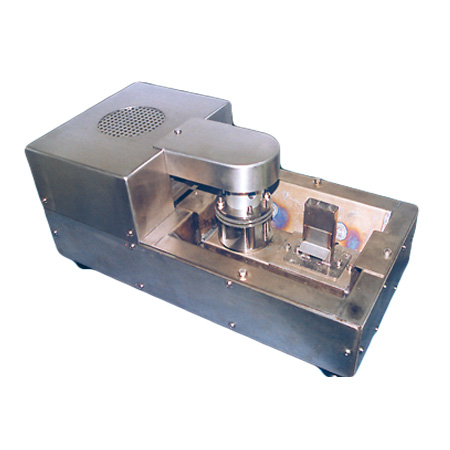

Overall dimensions W x W x H : 370 x 240 x 280 mm

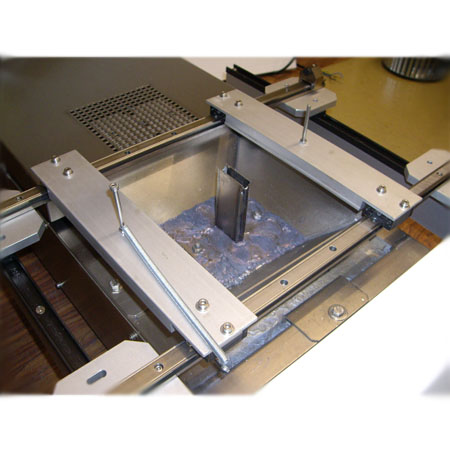

Alloy capacity 12 Kg

Accepts a nozzle up to 70 x 70 mm*

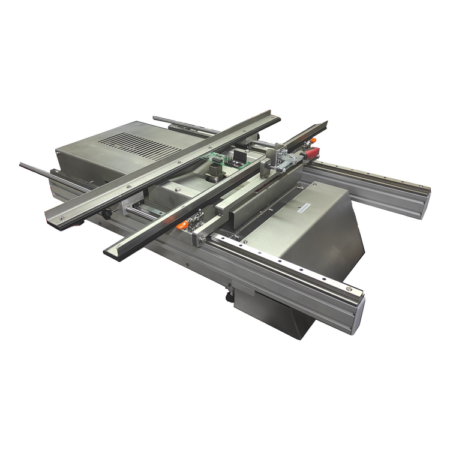

Maximum dimensions of the PCB 160 x 500 mm

Maximum temperature 400°C

Heating time 45 minutes

* The dimensions may be different. For example, if we reduce the length of the nozzle, it is possible to increase the width while keeping tthe surface of the nozzle