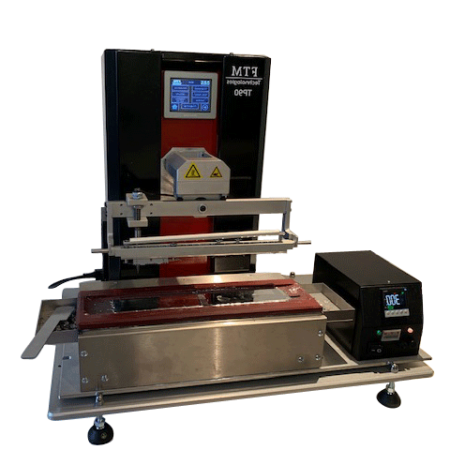

Automatic tinning machine for small and medium series

FTM Technologies has developed a tinning system for conveying components during tinning, de-coating or fluxing operations.

Thanks to the TP60P robot and now the new TP90 programmable automaton, it is possible to adjust the speed of entry, exit, preheating and immersion time. These precise settings make it possible to avoid bridging.

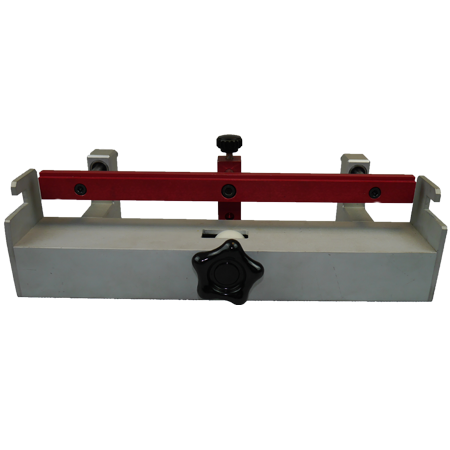

The use of component holders also makes it possible to gain productivity.

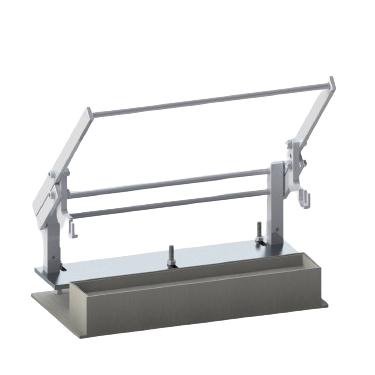

The complementary use of a pantograph makes it possible to manage the fluxing.

FAQ – FTM Technologies Tinning Systems (TP90, TP60P, pantographs)

What is an automated tinning system used for?

FTM tinning systems (TP90, TP60P or manual pantographs) perform precise and repeatable tinning of components, connectors, wires or pins.

They ensure de-golding, cleaning and tin reflow under automatic control of parameters: time, speed, temperature and immersion depth.

How does the TP90 tinning robot work?

The TP90 is a thermoregulated still bath tinning robot integrating a stepper motor precise to 0.1 mm.

The standard cycle includes:

- Program selection according to the component

- Controlled fluxing and preheating

- Automatic tin level detection (titanium sensor)

- Immersion and withdrawal at adjusted speed to avoid peaks

- Raising, air blowing and unloading

All steps are managed through a touch human-machine interface and can be stored for each series.

What types of components can be tinned?

FTM tools and fixtures allow adaptation to a wide variety of components:

- SMDs, QFPs, Flat Packs, coils, wires, connectors, lugs…

- Hybrid or sensitive components thanks to holder bars

- Elements with gold-plated pins requiring pre-de-golding

The TP90 tool holders are compatible with previous TP60P models and manual pantographs.

How is the complete tinning cycle organised?

A typical cycle includes:

- Loading of the component holder tool

- Fluxing (application of activating flux)

- Preheating to activate the flux and stabilise temperature

- Dip No. 1: de-golding (removal of gold or oxides)

- Cooling / Intermediate cleaning

- Second fluxing and final preheating

- Dip No. 2: tinning (SnPb, SnCu, SAC305…)

- Air blowing / Rinsing / Cooling

- Automatic unloading of the component

The whole process takes place under precise control of speed, time and temperature via the TP90.

Which additional equipment is compatible?

- Thermoregulated static solder baths: BE300×50, BE300×50D, BE300×90

- Flux tank or overflow fluxer with manual pantograph

- Interchangeable fixtures and component holder bars

- Tool loader for handling several bars at once

These accessories ensure repeatability and precision suitable for aeronautical or space applications.

What are the advantages of the TP90 system?

- Repeatability <0.1 mm thanks to the stepper motor

- Individual programming by component type

- Prevents tin bridges and “legs”

- High safety: operation prohibited if temperature is insufficient

- Simple and intuitive touch interface

What are the manual or semi-automatic alternatives?

For occasional or prototype needs:

- Manual pantograph with single or double tank bath (BE300×50, BE300×50D)

- TP60P, semi-automatic version prior to TP90

- Flux tank with pantograph for precise fluxing with low consumption

Which fluxes and alloys are recommended?

Depending on the nature of the pins and the desired finish:

- Cleaning or reducing fluxes suitable for electronic components

- Standard alloys: SnPb, SnCu, SAC305, SnAgCu

- Typical working temperature: 80–120 °C for fluxing, 450–520 °C for tinning

FTM baths are compatible with lead-free and leaded alloys.

Which industries use these systems?

- Electronics manufacturing, connectors, aeronautics, space

- Maintenance and board reconditioning

- Production of tinned harnesses or lugs

The TP90 automation is integrated into a complete FTM set (bath + flux tank + fixture) to ensure the reliability and cleanliness of industrial tinning.

- Display 36 Products per page