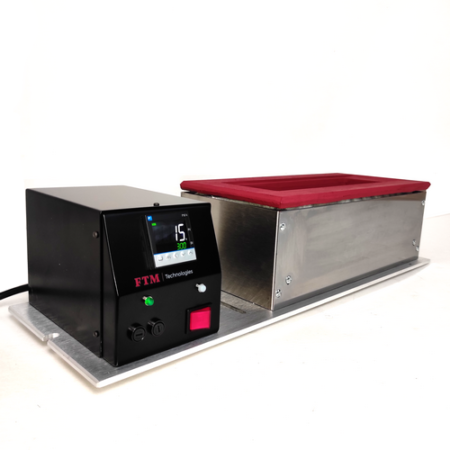

Mains supply : 230 V / 50-60 Hz

Power : 1600 W

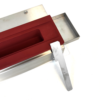

Working dimensions L x W x H : Crucible 300 x 50 x 45 mm

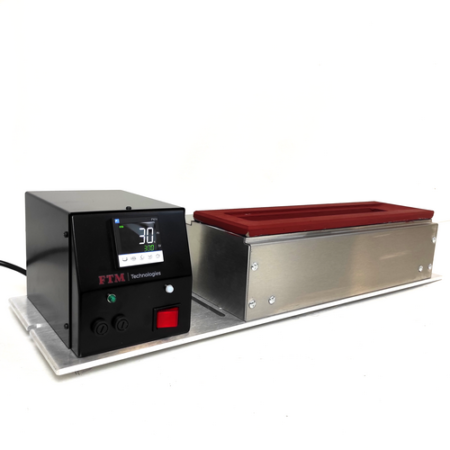

Overall dimensions L x W x H : 640 x 200 x 150

Weight of solder : About 5 kg

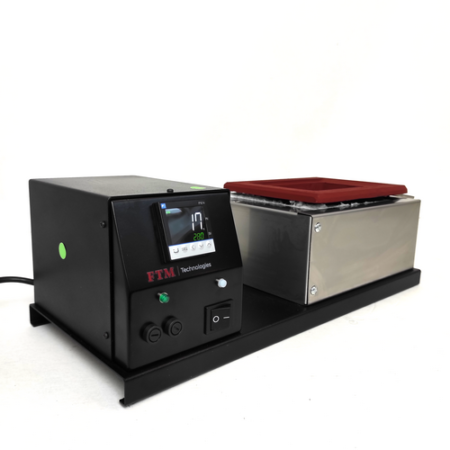

PID adjustment : from 0° to 600°C with adjustable setpoint

PE600NAD thermoregulated static soldering pot

PE600NAD thermoregulated static soldering pot