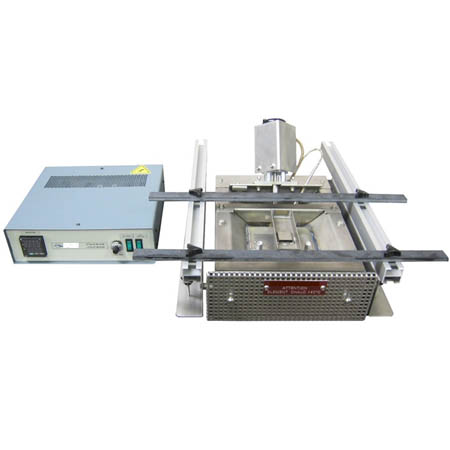

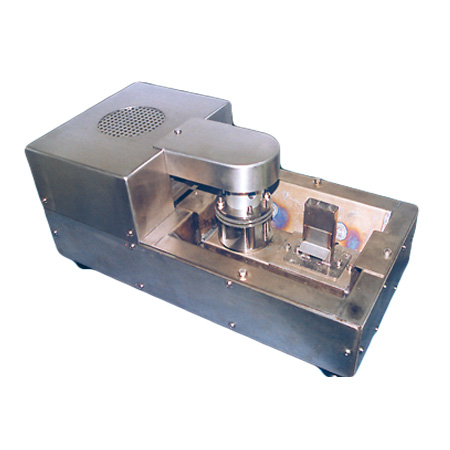

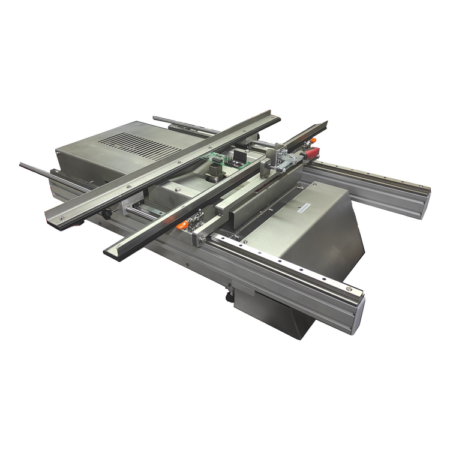

Selective miniwaves for tinning, soldering, rework

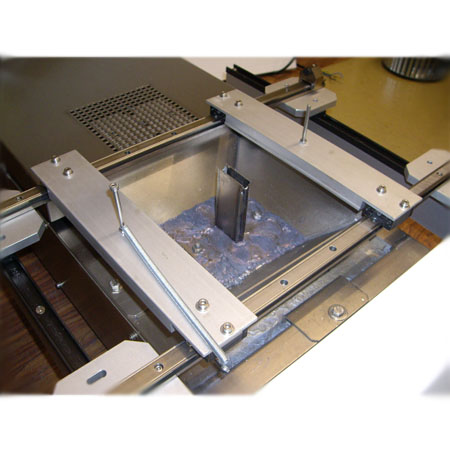

An alloy is introduced into the tank, to melt, out through the nozzle and form an extremely smooth wave. This process allows the welding or desoldering of components without affecting or damaging neighboring components and allows for continuous a tin surface without any impurity.

Mini Waves are also production machines for brazing complex components requiring adapted multi-jet nozzles.

These selective Mini-Waves are made of titanium, to reach very high temperatures and allow the welding and desoldering of components with precision and cleanliness.

– Compact

– Many applications (lead-free soldering, repair work, production lines)

– Safe : setting the temperature of the bath with a digital screen, the power and the height of the wave, the immersion time in the wave.

– Possible addition of additional accessories (fluxing at constant level, nitrogen cover…)

All our products are compatible with lead-free alloys.

- Display 36 Products per page