The Joule soldering or resistance soldering is a complementary tool to the traditional soldering iron

A powerful current and very low voltage achieves immediate heat localized through the electrodes.

Our different models will give you a better control of the heat and a speed of execution while avoiding the overheating of the components.

Particularly sought after for soldering coaxial connectors, this technology offers opportunities in many areas requiring significant spot heat.

FAQ – Resistance Soldering Stations SI1R & SI2R

What is the principle of resistance soldering?

Resistance soldering (Joule effect) consists of passing a high-intensity, very low-voltage current through a contact resistance at the soldering area. Heat is generated instantly and locally, without flame and without overheating sensitive components.

What are the advantages of the Joule effect process?

- Instant and localized heating (up to 1100 °C).

- No overheating of sensitive components.

- Flameless process, safer than conventional soldering.

- The pliers hold the parts and leave one hand free for tin.

- No continuously heated tool → low energy consumption.

- Reduced maintenance: electrodes last longer than soldering iron tips.

What models are available?

- SI1R: 80 W, 15 A, 2.1 V – for light and precise applications.

- SI2R: 250 W, 135 A, 1.9 V – for heavier or multi-strand soldering.

Each set includes: power unit, foot switch, insulated pliers and copper-plated stainless-steel electrodes.

What applications are possible?

- Connector soldering on semi-rigid cables.

- Central contacts of coaxial connectors.

- Assembly of multiple strands or multi-pin connectors.

- Soldering of sensitive connections and high-frequency cables.

- Tinning of copper strips or pre-tinned pads.

How does the soldering operation take place?

The parts are gripped with the pliers, the foot switch is pressed to start heating, then a small amount of solder is added. Heating stops as soon as the switch is released. Temperature depends on the wire section and the pulse duration.

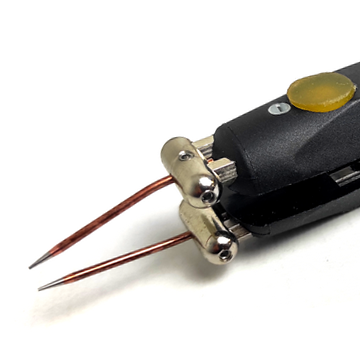

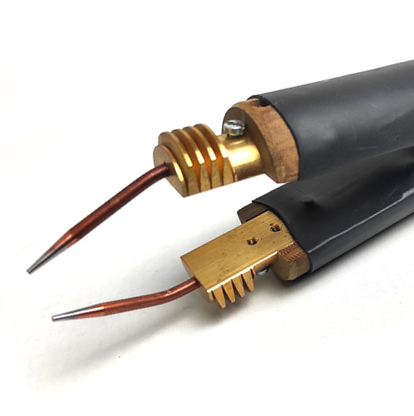

Which pliers and electrodes are compatible?

- SI1R → PCSR pliers with ESI1R electrodes (set of 5 pairs) or ESI1P (flat).

- SI2R → PCSI2 pliers with ESI2R electrodes (set of 3 pairs).

What settings are available?

A potentiometer adjusts the heating power according to the wire type and section.

The pulse duration is controlled by the foot switch, ensuring precise control of temperature and melting.

What maintenance is recommended?

Electrodes must be cleaned regularly using the supplied metal brush and replaced when wear or oxidation appears.

Periodically check pliers tightening and the cord. No other specific maintenance is required.

What safety devices are included?

- Full pliers insulation (polyamide 6×6).

- Very low output voltage (1.9 to 2.1 V).

- Internal fuse protection (3.15 A).

- No standby or continuous heating of the pliers.

Do the soldering stations require heavy maintenance?

No, they are almost maintenance-free. The only operations are cleaning electrodes and checking the pliers. Electrode lifetime is much longer than that of a soldering iron tip.

- Display 36 Products per page