EXPLANATORY NOTE ON THE USE OF FILTERS IN OUR EXTRACTOR HOODS – ALL OUR HOODS OPERATE IN 2 VERSIONS

-

External discharge

In this case, a 125 mm diameter nozzle is fitted at the rear of the appliances to attach a pipe which is connected to the exterior of the building or the room where the pollutants are emitted, so they can be channelled out and evacuated.

For safety reasons, we would recommend using a dust filter (ref : FPP1) in the appliance to :

– Protect the turbine from the risk of getting fouled or blocked by the fall or suction by the turbine of an object which could block it or damage the blades

– Protect the operator at his station against the risk of any kind of accident, as the turbine rotation is open to the air (e.g. suction of any hair, projection of objects fallen into or sucked up by the turbine…)

-

Discharge into the work premises after filtration

If the filtration option is chosen, it is essential to know what pollutants will be picked up in order to decide which filter to use.

This choice depends on :

– The nature of the pollutant (vapour, dust…)

– The concentration emitted

– Its Power to be adsorbed by the filter

– The replacement rate of filters over time

DIFFERENT TYPES OF FILTERS – USE

-

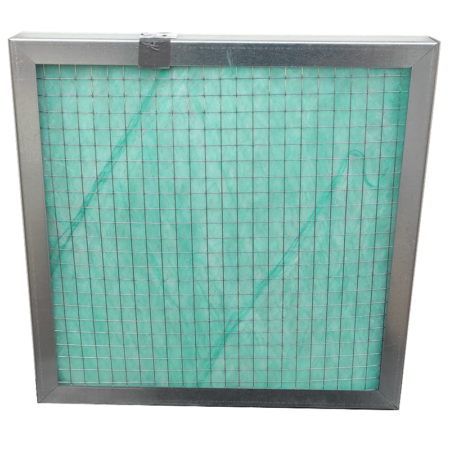

Active charcoal filter

– Ref : FCP1 : For all hoods except HI8

– Ref : FC2 : For HI8 hoods

The active charcoal filter is used to eliminate noxious or unpleasant smells emanating from liquids, vapours or smoke.

To find out the efficiency of the filter in relation to the pollutant to be processed, we have drawn up a list of the main products with which we are most often confronted (see attached table).

The a – b – c – d classification of adsorption rates is empirical, but generally the products classified c and d are perfectly well filtered by active charcoal.

Please consult us about any products that do not appear on this list. -

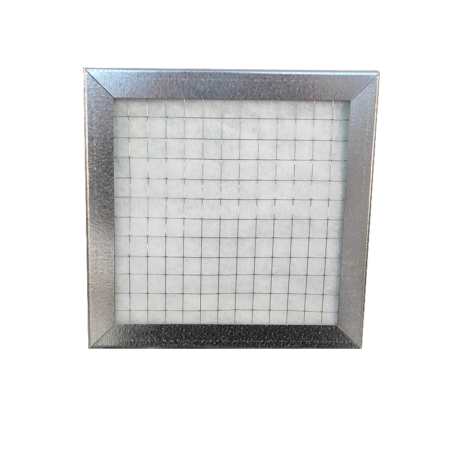

Dust filter

– Ref : FPP1

These have 2 uses :

– In the case of external discharge (see external discharge section), protective

– As their name indicates, to pick up particles suspended in the air, emanating from either grinding or scraping, or from powder handling…

This filter stops down to 1 µ granulometry with excellent percentage results -

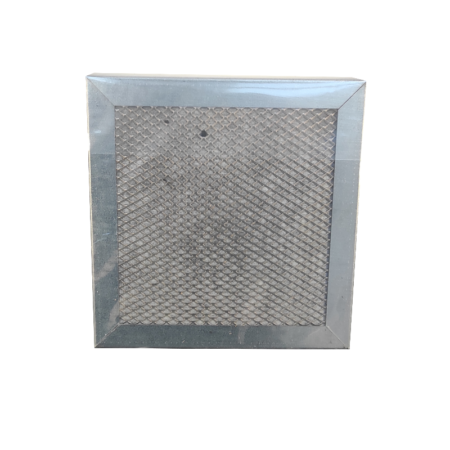

Aerosol filter

– Ref : FAP1 : For all Hoods except HI8

– Ref : FA2 : For HI8 Hoods

To use in the same circumstances as the FP/P1 filters, but these pick up particles with a granulometry far below (smoke collection, for instance). -

Pre-filters

– Ref : PFP1 : For all Hoods except HI 8

– Ref : PF2 : For HI 8 Hoods

The aim of this filter is to protect the active charcoal filter against particles, so as to prevent the surface of the filter becoming clogged.

- Display 36 Products per page