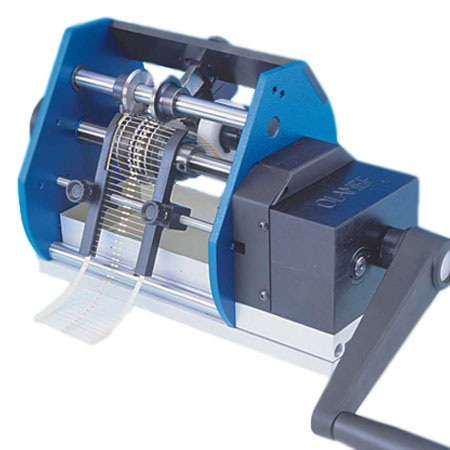

FTM Technologies offers specially designed bending and cutting machines for axial and radial components

The complete OLAMEF range offers simple and reliable machines for manual or automatic component processing.

Submit us your components and your requirements of bending, we will propose you the machine and its adapted tool.

You will also find component counting machines, printed circuit depanelisation and other accessories.

FAQ – Axial & Radial Lead Forming and Straightening Machines

What is the difference between axial and radial components?

Axial components (e.g., resistors, diodes) have two leads aligned on opposite sides of the body. Radial components (e.g., capacitors) have two leads exiting from the same side. Machines are designed specifically for each component geometry and feeding method.

Which machines should be used for axial components on tape?

For taped axial components, automatic forming and cutting machines are recommended. The right model depends on the required lead shape, tolerances, and production rate.

What about radial components?

Radial forming machines can process bulk or taped components, shaping and cutting the leads to match PCB insertion requirements. Both rotary and linear systems are available depending on the task.

What lead diameters can be processed?

Standard models handle wires from approx. 0.4 mm to 1.3 mm. Reinforced versions allow processing of thicker or harder wires. Exact values depend on the selected model.

What productivity can I expect?

Typical throughput ranges from 2,500 to 20,000 components per hour depending on the machine, operation type and feeding method (manual, taped, or motor-driven).

Do the machines require special maintenance?

Maintenance mainly consists of cleaning and replacing wear parts such as knives, rollers or brushes. This ensures consistent and precise forming over time.

Can the machines be adapted for specific components?

Yes. Many models can be equipped with custom tooling for special shapes, pitches or dimensions to meet specific PCB design requirements.

What is the difference between standard, reinforced and EC versions?

Standard versions cover most applications. Reinforced versions are suitable for higher forces and harder leads. EC versions offer a simplified and cost-efficient design for moderate workloads.

Can the machines be motorized?

Yes. Many machines can be retrofitted with a motor or integrated into automatic feeding systems to increase production speed and ergonomics.

Are special lead forming shapes available?

Yes. Special shapes are available on request, including custom standoff heights, polarity bends, and insertion pitch adaptations.

Are OLAMEF models compatible with each other?

Many tools and accessories are compatible across OLAMEF models within the same series. Compatibility should be confirmed for each specific configuration.

How do I select the right model?

Selection depends on component type (axial/radial), production volume, lead diameter, desired shape and whether motorization is needed. The technical data comparison helps identify the optimal solution.

- Display 36 Products per page