All solutions for the mechanical stripping of enamelled wires

FTM Technologies presents its range of de-enameling devices for mechanically removing the layers of enamel or varnish covering the copper or aluminum wires.

Our selection of products covers a wide range of diameters and shapes. The proposed techniques are brushing or the use of cutting tools.

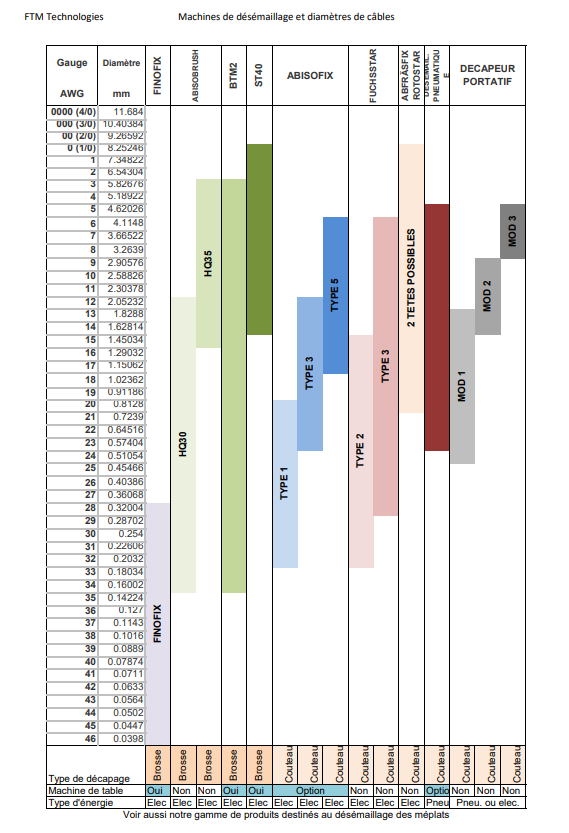

Consult the summary table of our tools to help you define the tool for your needs.

In case of doubt, our workshop is available for customers to carry out additional tests.

FAQ – Enamel Wire Stripping & Descaling

What is enamel stripping?

Enamel stripping consists of removing the insulating enamel layer from a copper or aluminium wire before brazing, tinning or soldering.

FTM Technologies offers mechanical and rotary solutions that avoid the use of flames or chemical solvents.

Do you have round wires or flat conductors?

The choice of equipment depends first on the shape of the conductor:

- Round wires: Abisofix, Abfräsfix, Abisobrush HQ, Fuchs Star, Finofix, ST40.

- Flat wires / strips / bars: Abisobrush HQ35P, BTM2, ST40, rectangular stripping pliers.

For borderline cases (large diameter, very hard enamel, rectangular conductor), refer to the FTM enamel-stripping summary table supplied with the documentation.

What are the main available machines?

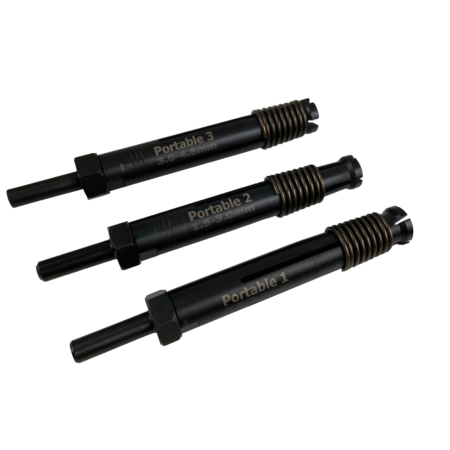

- Abisofix: handheld device with interchangeable heads for round wires.

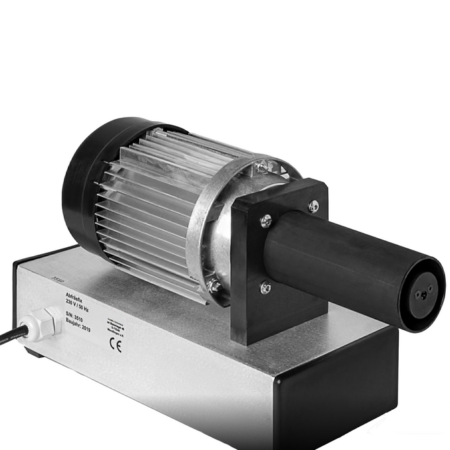

- Abisobrush HQ30 / HQ35P: rotary brushes for round and flat wires.

- Fuchs Star: fast electric blade tool for varnished round wires.

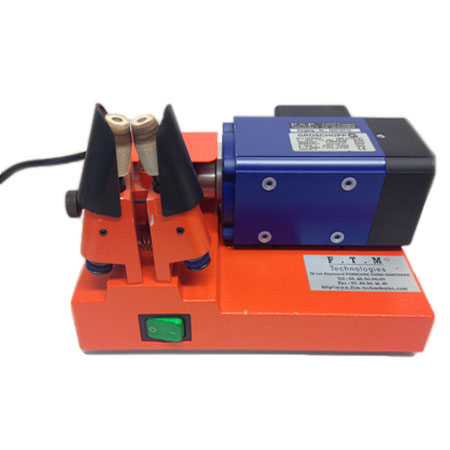

- BTM2: silent benchtop steel-brush machine for round and flat wires.

- Abfräsfix: automatic knife-based machine for very hard enamel.

- ST40: benchtop machine for larger-section round and flat wires.

- Pneumatic pliers: for fast stripping of round wires.

- Rectangular pliers: for stripping flat wires or conductive bars.

- Portable stripper: mobile solution for on-site work or maintenance.

How do I choose the right machine?

Selection is based on 3 criteria:

- Wire shape: round or flat

- Enamel type: standard, polyimide, thick layer

- Productivity: workshop workstation, small batch, or production line

The FTM enamel-stripping reference table indicates for each machine the supported cross-section ranges and enamel hardness. It is the tool to rely on.

What is the difference between brush-based and knife-based systems?

- Rotary brushes (HQ, BTM2, ST40): progressive, very gentle stripping, ideal to preserve copper integrity.

- Knives / cutters (Abfräsfix, portable stripper): more incisive, recommended for thick varnish, large-section wires, or partial stripping.

Do the machines require a lot of maintenance?

No. Regular cleaning of brushes or knives and the replacement of wear parts when necessary is sufficient to ensure consistent performance over time.

- Display 36 Products per page