Segmented extraction arm system for multi-station box installations.

– Consisting of acetal copolymer segments, the Locline arms are similar to the Omniflex system.

– Adjustable by hand

– Easy to position thanks to their segment-based design

– Very rigid

– Possibility to extend

– Several models of adaptable nozzles

– Outside diameter : 74.5 mm

– Inner diameter: 62mm

– Minimum bend radius of 146 mm

– Standard version (blue) or ESD (black)

– To be used with HI4P4S hood (4 outlets) or HI-HEPA

– To be used with our multi-station hoods

FAQ – Segmented Extraction Arms

What is a segmented extraction arm used for?

A segmented extraction arm captures fumes, dust, vapours and particles directly at the source.

Flexible, adjustable and easy to orient, it is used for soldering, brazing, tinning, oil mist removal or chip extraction.

It improves air quality and protects the operator.

Flexible, adjustable and easy to orient, it is used for soldering, brazing, tinning, oil mist removal or chip extraction.

It improves air quality and protects the operator.

What is the difference between the standard and the ESD version?

- Standard (blue): general industrial use.

- ESD (black): Loc-Line antistatic material — surface resistivity 1×10³ Ω, volume resistivity <6×10² Ω·cm.

Provides rapid dissipation of electrostatic charges (when properly grounded).

Ideal for electronic workstations and ESD-sensitive environments.

What is the arm made of?

Manufactured from acetal copolymer: rigid, lightweight, resistant to petroleum products and fully modular by adding or removing segments.

⚠️ Not compatible with strong acids.

⚠️ Not compatible with strong acids.

What are the main technical characteristics?

- Standard length: 770 mm

- Inner diameter: 62 mm

- Outer diameter: 74.5 mm

- Bend radius: R 146 mm

- Max operating temperature: 80 °C

- Melting point: 165 °C

Is the arm modular?

Yes. Thanks to its removable segments:

- +9 upper segments = +300 mm additional length

- Compatible with all FTM nozzles and accessories

Which accessories are available?

- Long nozzle (150 mm): Standard 81 205 / ESD 81 305 — precise extraction

- Round nozzle (Ø119 mm): Standard 81 203 / ESD 81 303 — localised capture

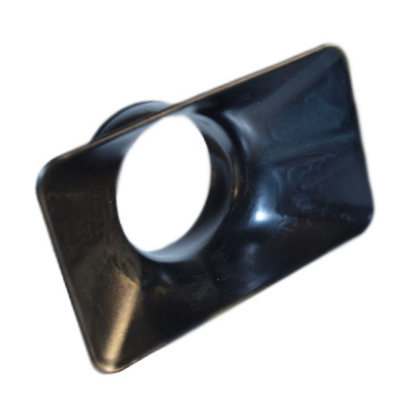

- Rectangular nozzle (157×93 mm): Standard 81 204 / ESD 81 304 — surface extraction

- Large rectangular nozzle (365×218 mm): ESD 81-304MOD — extended capture zones

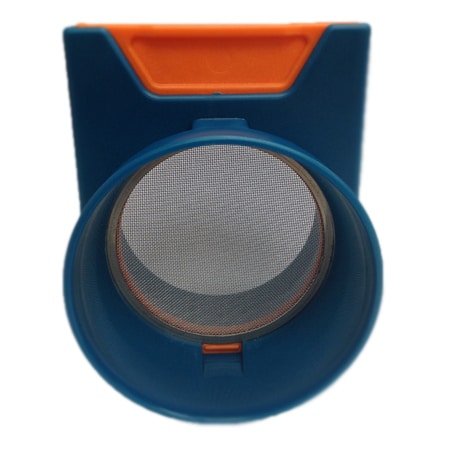

- Flow regulator with mesh filter: Standard 81 208 G315 / ESD 81 308 G315 — flow adjustment

- Table clamp support: BF / BF ESD — quick bench mounting

What is the maximum operating temperature?

Up to 80 °C continuous use (melting point 165 °C).

Suitable for soldering and tinning operations, but not for effluents exceeding 80 °C.

Suitable for soldering and tinning operations, but not for effluents exceeding 80 °C.

Is the ESD arm certified?

Yes. Loc-Line components are tested and certified antistatic.

“The material rapidly dissipates static electricity when properly grounded.” (Lockwood Products, 2007)

“The material rapidly dissipates static electricity when properly grounded.” (Lockwood Products, 2007)

Can several arms be combined or connected to an extraction box?

Yes. Arms can be connected to a standard or reinforced extraction box,

or integrated within a multi-arm capture network with individual shut-off valves.

or integrated within a multi-arm capture network with individual shut-off valves.

Typical applications?

- Soldering, tinning, brazing

- Gluing, light spraying

- Laboratories and ESD workstations

- Assembly and maintenance workshops

- Processes emitting vapours or micro-particles

💡 Tip: Segmented arms offer precise, adjustable local extraction while maintaining excellent flexibility and compatibility with a wide range of nozzles.

- Display 36 Products per page