Range of standard tin baths (cast iron) or bespoke baths (titanium)

The operation of tinning involves applying a thin layer of tin-based alloy on a metallic part. These means also allow to perform operations of De-enamelling and degolding.

Special needs ? We realize your tailor-made tin bath according to your needs of production, contact us !

All our products are compatible with lead-free alloys.

FAQ – Static Tin Baths (FTM)

What is a static tin bath used for?

For immersion tinning of wires, lugs, connectors and small copper or alloy parts, as well as for degolding or pre-tinning before soldering.

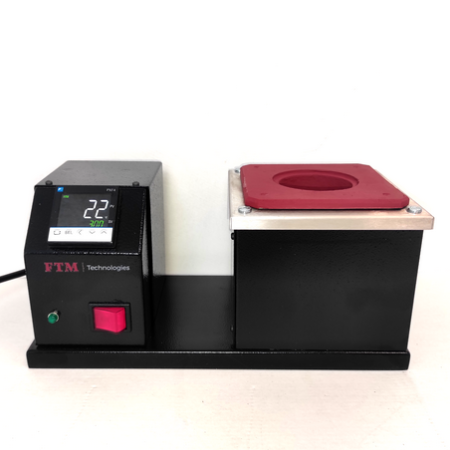

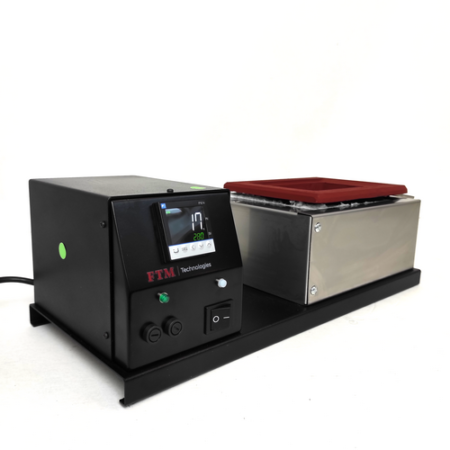

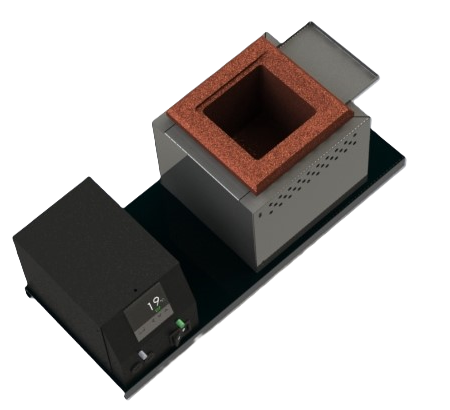

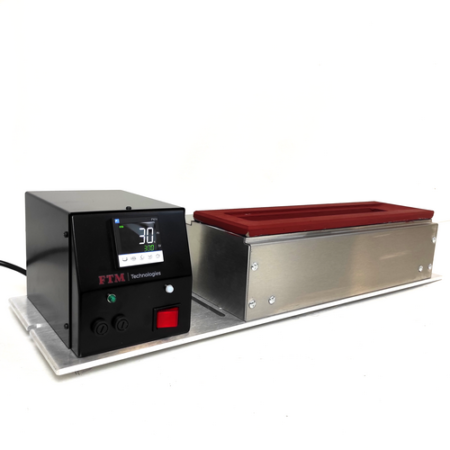

Which models are available?

Summary of main bath models:

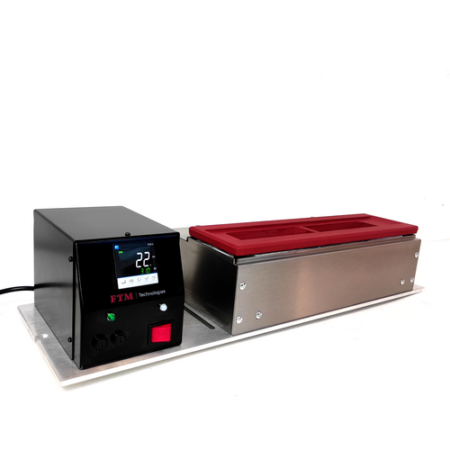

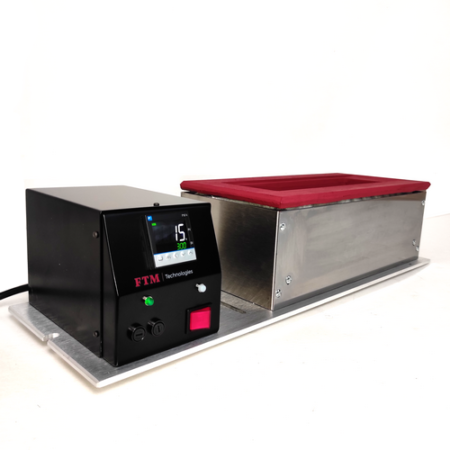

- BE300×50 – standard rectangular bath.

- BE300×50 double – same characteristics as BE300×50, tank divided in two (two alloys / two steps).

- BE300×90 – high power 2400 W for larger parts.

- BE600N – tank 150×100×55 mm, power 1600 W.

- BE100 – tank 100×100×100 mm, power 1200 W.

All models are benchtop units, easy to integrate into tinning workstations.

What is the maximum temperature?

Up to ≈ 520 °C working temperature, covering most alloys (including lead-free).

Why choose a double tank (BE300×50 double)?

To use two alloys at the same workstation, separate clean / loaded baths, or perform two successive operations (e.g. degolding → tinning) without changing setup.

Which alloys can be used?

Lead-free (RoHS compliant) and SnPb alloys (maintenance / exempt applications). Available in bars or ingots compatible with FTM baths.

What is the difference with a rotary bath?

The static bath is simple and economical for moderate production rates.

The rotary model keeps the tin surface continuously clean (scraping) and speeds up repetitive series.

How is the temperature controlled?

By integrated PID regulation: fast heating and stable maintenance around the set temperature (up to ≈ 520 °C).

What precautions and maintenance are required?

Heat protection PPE (gloves/goggles), stable and ventilated workspace, regular oxide scraping, tin refilling, and periodic check of wiring and thermostat.

| Model | Bath dimensions (mm) | Power | Features |

|---|---|---|---|

| PE500 | Ø60 × 60 | 500 W | Small round pot for wire ends or small parts; used with RP500 power controller |

| PE600NAD | Ø60 × 60 | 600 W | Thermoregulated round pot (PID 0–520 °C, type-J thermocouple); narrow and deep geometry for vertical tinning |

| Rectangular baths | |||

| BE100 | 100 × 100 × 100 | 1200 W | Deep rectangular bath, ideal for larger parts |

| BE300×50 | 300 × 50 × 45 | 1600 W | Standard bath for wires and connectors |

| BE300×50 double | 2 × (145 × 50 × 45) | 1600 W | Split tank for double alloy or two-step tinning (degolding + tinning) |

| BE300×90 | 300 × 90 × 45 | 2400 W | High capacity, suited for heavy or massive parts; excellent thermal inertia |

| BE600N | 150 × 100 × 55 | 1600 W | Wide format, ideal for long wires or terminals |

- Display 36 Products per page