Selective miniwaves for tinning, soldering, rework

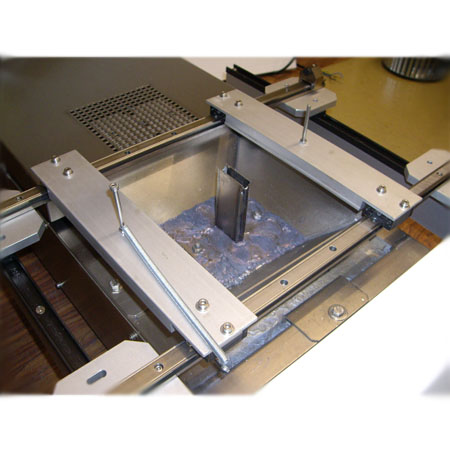

An alloy is introduced into the tank, to melt, out through the nozzle and form an extremely smooth wave. This process allows the welding or desoldering of components without affecting or damaging neighboring components and allows for continuous a tin surface without any impurity.

Mini Waves are also production machines for brazing complex components requiring adapted multi-jet nozzles.

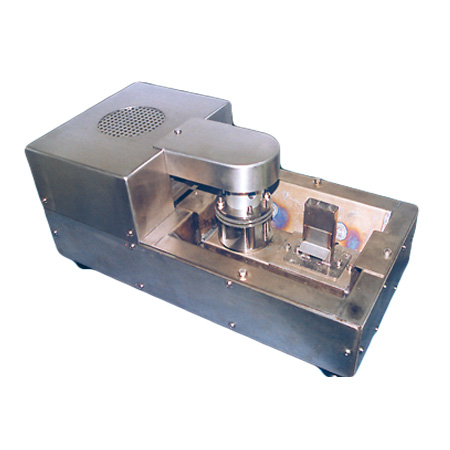

These selective Mini-Waves are made of titanium, to reach very high temperatures and allow the welding and desoldering of components with precision and cleanliness.

– Compact

– Many applications (lead-free soldering, repair work, production lines)

– Safe : setting the temperature of the bath with a digital screen, the power and the height of the wave, the immersion time in the wave.

– Possible addition of additional accessories (fluxing at constant level, nitrogen cover…)

All our products are compatible with lead-free alloys.

FAQ – Selective Mini-Waves MV100 and MV500

What is a selective mini-wave used for?

It can also be used for enamel stripping by thermal shock (“enamel cracking”) on copper or aluminium wires, using a suitable nozzle and carefully controlled contact time.

What are the differences between the MV100 and MV500 models?

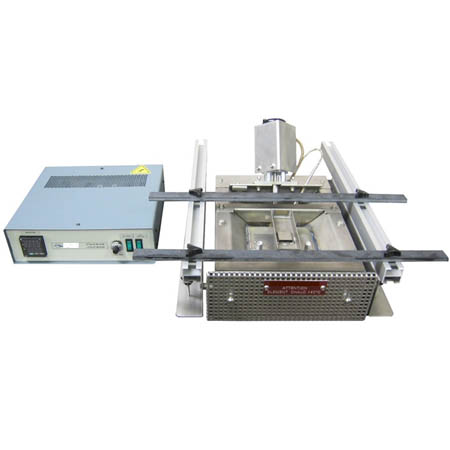

- Compact mini-wave for rework, small batches and precision work.

- Alloy capacity of around 12 kg.

- Maximum nozzle size: 125 × 20 mm.

- Boards up to approx. 160 × 500 mm.

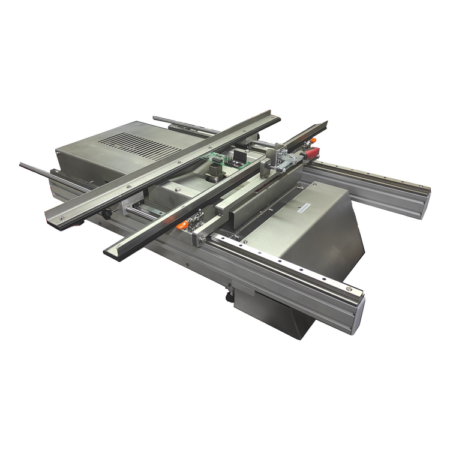

MV500:

- Larger mini-wave for boards up to 500 × 600 mm.

- Alloy capacity of around 45 kg.

- Maximum nozzle size: 200 × 20 mm.

- Suited to heavier-duty use or production environments.

Which versions are available for the MV100?

- MV100 standard: maximum temperature 300 °C, suitable for most common solder alloys.

- MV100-GD5: reinforced version allowing operation up to 500 °C, recommended for demanding applications.

- MV100 pack with fluxer: configuration including the mini-wave and a dedicated fluxing system for a complete selective soldering process.

Which versions are available for the MV500?

- MV500 (standard version): mini-wave with classic control box, adjustment of temperature and pump speed.

- MV500-HG01: separate cabinet with touch screen, setting of “work” and “standby” pump speeds, solder wave time and temperature thresholds.

- MV500-HG02: high-end version with programme storage, frequency inverter on the motor and separate electrical cabinet; each programme stores the main process parameters.

What applications are the MV100 and MV500 mini-waves recommended for?

- selective soldering of through-hole components on electronic boards;

- clean, localised desoldering for repair and rework;

- prototype and small-batch production;

- thermal enamel cracking on enamelled wires, to expose copper on a precise area;

- any process requiring finely controlled contact time and wave height.

What types of nozzles can be used?

- narrow nozzles for fine work and enamel cracking;

- rectangular or square nozzles for larger zones;

- long nozzles (up to 125 mm on MV100, 200 mm on MV500);

- special or custom nozzles adapted to the board design.

The nozzle choice depends on the area to be treated, the component layout and the required precision.

What accessories are available for the MV100 and MV500?

- Heating timer to preheat the bath before the shift.

- Foot pedal to trigger the cycle while keeping both hands on the board.

- XY table and adjustable board holder (especially with MV500) for precise PCB positioning.

- Pneumatic or electric lift to adjust the wave height.

- Laser pointer to locate the exact impact area of the wave.

- Nitrogen hood and diffuser to reduce alloy oxidation.

- Thermal covers for the bath and other safety or comfort accessories.

Which alloys and temperatures can be used?

- MV100 standard: up to 300 °C.

- MV100-GD5: up to 500 °C.

- MV500 (all versions): up to 300 °C.

Alloy choice and temperature settings depend on the components, PCB materials and process requirements.

What are the main safety precautions?

- wear thermal gloves, eye protection and suitable clothing;

- never introduce objects or liquids into the solder bath;

- avoid jewellery and loose items that could trap heat or get caught;

- use adequate fume extraction when fluxes and solder fumes are present;

- switch off and isolate the unit before any maintenance work.

What maintenance is required on a mini-wave?

- regular inspection of cables, connectors and control devices;

- periodic cleaning of the nozzle and overflow zones;

- monitoring of the pump body (impeller, graphite bush, bearings) and replacement of wear parts if necessary;

- checking heaters and the thermocouple if temperature deviations appear.

Simple preventive maintenance helps to keep a stable, smooth and repeatable solder wave over time.

thermal enamel cracking on enamelled wires, with adapted nozzle, wave height and contact time.

- Display 36 Products per page